OUR STORY

Custom Beach was founded by Thomas Bache-Wiig, a native Norwegian with a Scandinavian design and construction background. He’s a professionally trained carpenter, contractor & design architect with a Bachelors of Architecture from Cornell University and more than 30 years of industry experience.

Since designing and building the first beach hut in the backyard in 2009, Custom Beach has grown to become a trusted brand among industry leaders in the hospitality industry, and we have been fortunate to serve major brand hotels, condo associations and service providers across the US from Hawaii to the Hamptons, to the Caribbean and beyond.

Our high end customized products has proven to be cost efficient, low in maintenance and easy to operate. We carefully select materials that withstand the harsh beach & ocean climate. All our products are designed & built in Miami and we can deliver anywhere.

How we got started

Custom Beach began as a carpentry business making beach service huts for hotels on Miami Beach. These huts became popular, leading us to create various interior layouts, such as greeting huts with amenities and food and beverage huts with storage and POS systems. This innovation improved service speed, guest satisfaction, and hotel revenue.

We customized each hut to match the hotel's design, enhancing brand recognition and extending the hotel's presence to the beach. We also developed a custom solar panel system to power the POS computers.

From Beach to Pool

After years of building huts for 30-40 hotels, we expanded our product line to include matching waste bins and towel bins for the beach and pool decks.

Today, Custom Beach offers a range of products, including host stands, mobile bars, valet stands, and more, to help hotels provide excellent service to their guests.

Remaking how we make things

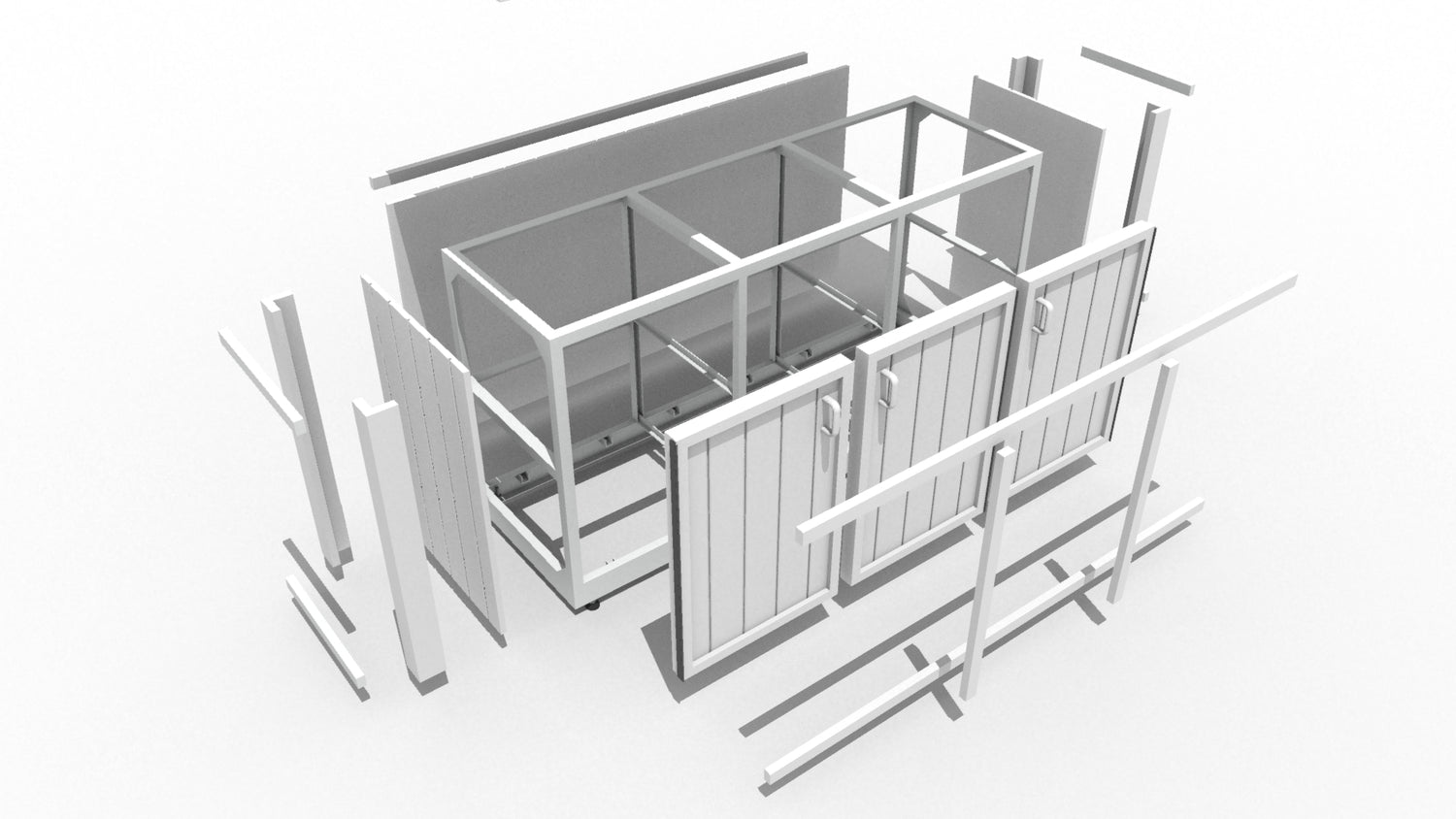

After 10 years of using traditional wood craftsmanship, we developed a new manufacturing technique where all components can be disassembled and replaced. This modular design features a welded and powder-coated aluminum frame with concealed stainless steel fasteners, resulting in lighter, stronger, and fully recyclable products. Components can be easily replaced for maintenance or aesthetic updates, making our products more durable and sustainable.

This approach aligns with the EU's new "right to repair" directive, which aims to reduce waste by ensuring that products can be repaired or components replaced[1]. We believe this is the future of manufacturing, leading to more durable, easy-to-maintain, and fully recyclable products.

Does this version capture everything you wanted to include? Feel free to make any adjustments!

References[1]Directive on repair of goods - European Commission